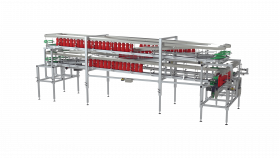

DBC202

Buffer conveyor

Ħtieġa

Buffering huwa importanti ħafna li jkollok Linja tal-imballaġġ effiċjenti ħafna. The need to buffer is increasing with today’s increasing speeds of packaging lines.

So how does this buffer conveyor increase line efficiency?

- Most importantly, by making the line immuni għal waqfiet mikro u ħinijiet ta 'rispons tal-operatur!

- Barra minn hekk, huwa jirrisolvi kwistjonijiet ta' tikkettar on HDPE lines (like bottle jinxtorob), as well as issues with magni tat-tirqim or palletizzaturi (frequent stoppages) ...

Bħala riżultat, itejjeb l-OEE jew Effettività ġenerali tat-Tagħmir.

But what does OEE mean?

Fil-qosor, OEE huwa mod kif tkejjel kemm tkun produttiva l-manifattura tiegħek. Billi tagħmel hekk, tista 'tuża dan l-għarfien biex ittejjeb il-proċessi ta' produzzjoni tiegħek!

OEE takes into account all losses of production. These losses can belong to one of three categories:

- disponibbiltà:

This measures production losses related to downtime. In other words, when the process stops running for some time. Because of changeover time, machine not running because of no sales, etc. - Prestazzjoni:

This measures production losses related to reduced speed. Because of slow cycles and micro stops. But our buffer conveyor DBC202 avoids such micro stops! - Kwalità:

This measures production losses related to produced units that you cannot release. Because the produced parts are defect or need rework.

For more information on OEE, you can check the following links: Effettività ġenerali tat-Tagħmir or OEE.com.

Il-magna

Length of this buffer conveyor: 36 meters.

Thanks to its control system, the DBC202 can work in different ways:

- Bħala buffer, biss switching għaliha meta jkun meħtieġ.

- Continuous troughput, buffer conveyor.

- Continuous troughput, cooling conveyor.

In fact, the speed is adjustable to switch between cooling & buffering.

Additionally, we can add loops multipli, single chain, to increase the capacity.

Furthermore, the DBC202 is available with gwida aġġustabbli u għata ta 'fuq għal ensure bottle integrity.

VANTAĠĠI

- Buffer conveyor with a modular system: cooling & buffering

- Impronta kompatta

- Espansibbli

- Increased line OEE!